How Different Packaging Technologies Reshape the VCSEL Market

Vertical-cavity surface-emitting lasers (VCSELs) shoot light straight out of the wafer like a flashlight, rather than sideways like edge-emitters. That vertical beam, plus tiny die size, unlocks smartphones’ face unlock, car LiDAR, and swarms of optical interconnects.

You might picture the die as a glowing grain of rice. Add the right housing and window, and that grain becomes a reliable light engine ready for automated pick-and-place.

Packaging shifts that steer the vcsel market

Market trackers peg global VCSEL revenue at about USD 2.3 billion in 2024 with double-digit annual growth projected through 2033

One huge growth lever is packaging: smaller, cooler, and smarter housings squeeze lasers into earbuds, watches, and even smart rings. Every new enclosure option widens the addressable pie, so packaging itself reshapes the vcsel market more than any single die tweak.

Why the race to shrink housing?

Boards in wearables and AR headsets fight for millimeters. A thinner lid or an array bonded directly onto a ceramic block can free just enough height to cross the design finish line. Lose the magnet in medical scanners and you unlock new MRI-safe trackers. Little tweaks, giant payoff.

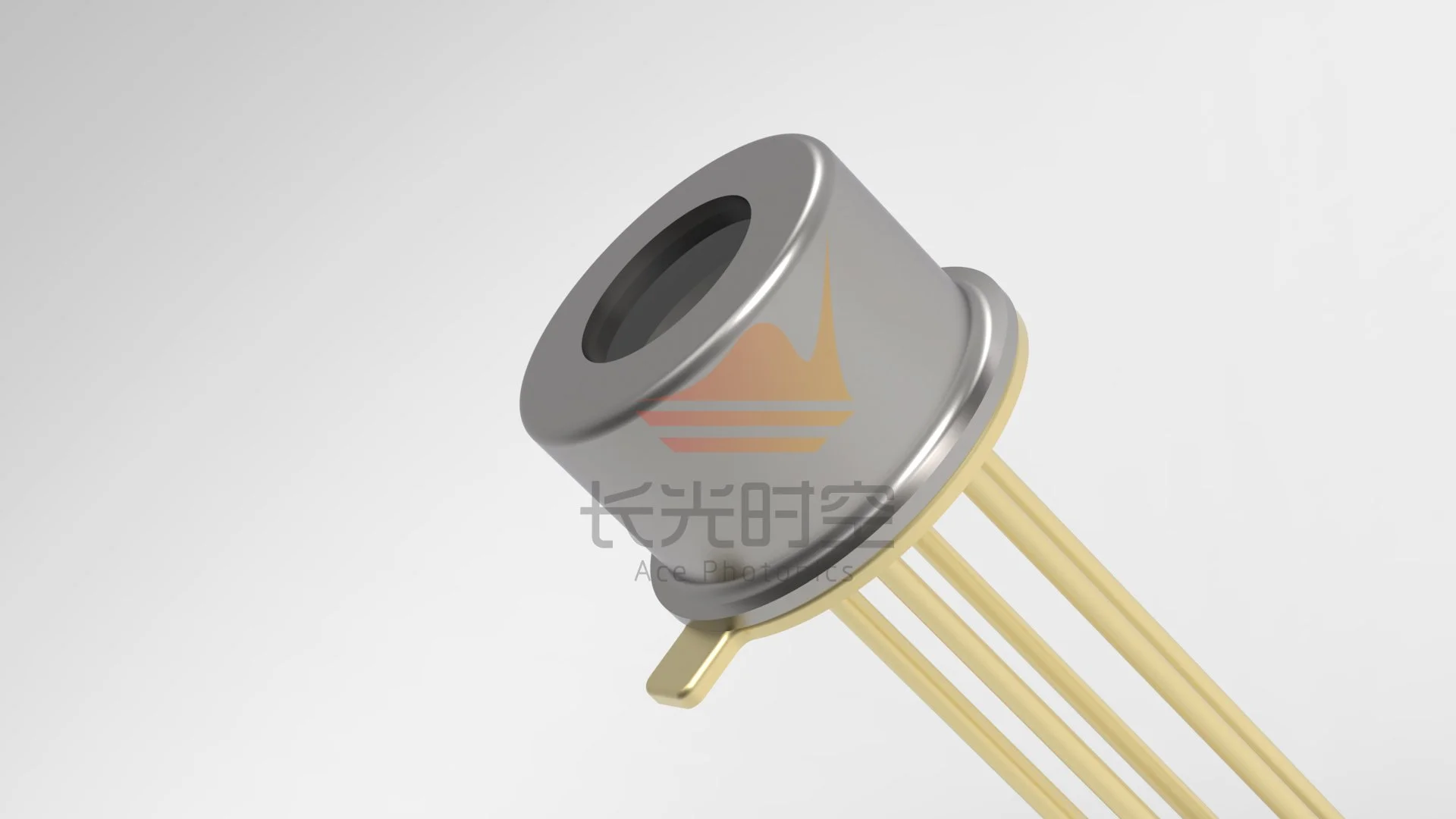

Classic TO-cans—small can, big promise

TO-46: the workhorse

The transistor-outline (TO) can rules datacom and sensing. A metal header, tiny post leads, and a ball lens or flat glass cap deliver a ready-made optical module. Vendors list sub-nanometer wavelength drift and gigahertz bandwidth, perfect for short-reach fiber and headset depth cameras .

Strengths

Mature supply chain

Hermetic seal keeps moisture out

Room for ball lens that narrows divergence

Ace Photonics custom twists: non-magnetic package, SMD, and more

At Ace Photonics Co., Ltd. we see requests far beyond standard cans. Here are three favorites we ship today:

Non-magnetic Package

Hospitals dislike steel near MRI bores. We drop ferromagnetic alloys and switch to titanium or CuW. Optical power stays stable while fields stay calm.

SMD Package

Want a VCSEL flush with the PCB? Our surface-mount land-grid adapts the die so solder paste printing and reflow feel exactly like mounting an LED. No manual post-assembly step needed.

Hybrid glass lid with AR stack

Dust can dull power over time. Our scratch-resistant borosilicate lid plus dual-side broadband coat keeps beams bright even in factory grit.

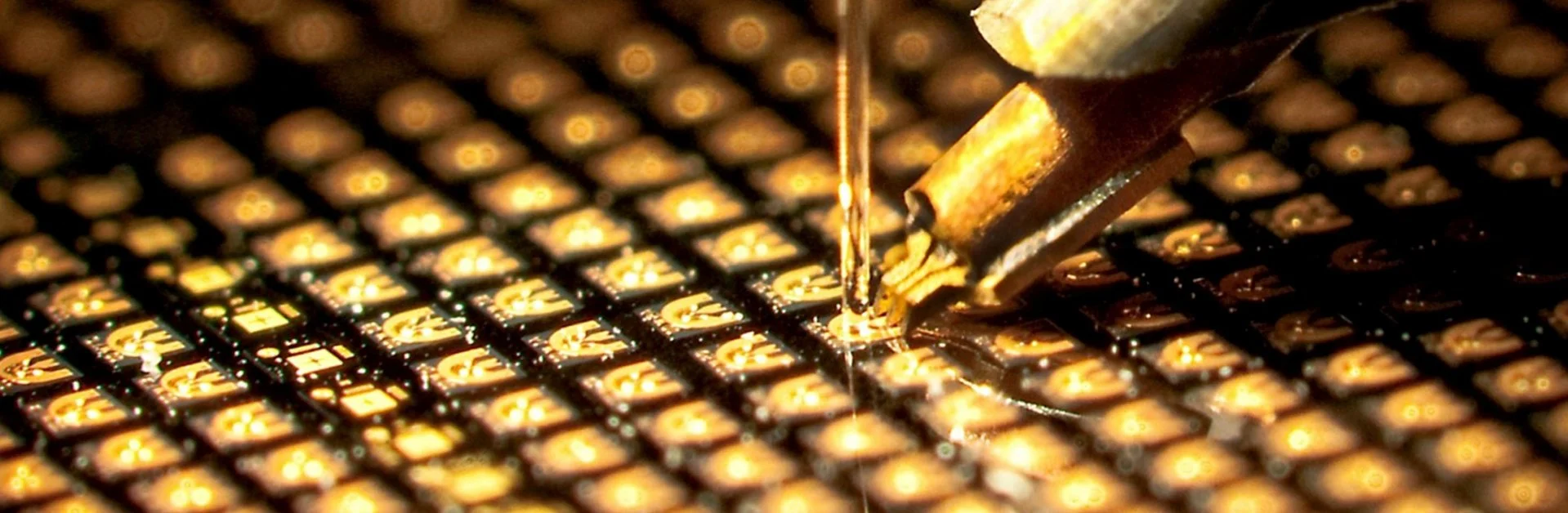

Wafer-level trends powering mass deployment

Flip-chip and through-glass via (TGV) caps

Instead of dropping each die into a metal can, wafer-level builds run lens forming, metallization, and encapsulation before dicing. Picture a cookie sheet of thousands of VCSELs, each already sealed and pre-aligned. That trim cuts unit cost and raises daily output, a must for phone makers shipping tens of millions each year.

How wafer-level caps amplify the vcsel market growth

No one wants to glue a million lids by hand. Batch capping drops minutes to seconds per part, unlocking price points once reserved for LEDs. This cost cliff invites entirely new consumer gadgets, accelerating the vcsel market rollout in AR glasses and smart-home lidar sensors.

Glass-on-silicon: a clear window with copper feed-throughs

Glass wafers drilled with copper vias act as both cap and electrical feed. The copper pillar’s low inductance helps drivers push faster eye-safe pulses, handy for automotive lidar units that need long throw beams .

Thermal stack cheats

Thinned GaAs die to shed joules faster

Silver epoxy under-fill to cut voids

Copper pillow heat spreader tied to package wings

Thermal hurdles and how packaging solves them

Heat kills laser efficiency. Packaging pulls heat out through high-conductivity paths and short bond lines.

Metal-core PCB carriers

Some clients swap the header for an AlN or Cu-backed pad inside an SMD frame. The board itself becomes the sink, clipping peak junction rise by double-digit Celsius numbers in burn-in trials.

Under-bump metallization upgrades

Thicker gold bumps and wide traces shave milliohms, so less I²R heat piles up. That inch-deep engineering detail keeps batteries smiling in wearables.

Optical windows: shaping light, blocking dust

Flat glass vs. ball lens

Ball lenses focus beams into tight cones, great for IR dots in depth cameras. Flat windows radiate wider and spread power thinly—ideal for gesture sensors needing a broad wash.

Anti-reflection coatings

A low-index matching layer trims Fresnel bounce, hiking power output while trimming ghost rays that might confuse image sensors.

Spectral filters for sunlight rejection

Stacked coatings can knock out specific solar lines, letting indoor tracking modules work under skylights without false triggers.

Reliability uplift through smart lids and adhesives

Low-outgassing epoxies

Outgassing can fog inner windows. Silicone-free epoxies keep lenses crystal-clear over thousands of operating hours.

Seam sealing with laser-welded glass

Laser welding fuses glass lids to Kovar frames, making a micro-oven for the die. That tight seam shrugs off humidity swings and freezer-to-oven shock, a must for automotive under-hood placement.

Cost breakdown and design trade-offs

Packaging shapes cost far beyond raw die expense. A TO-46 can may run a few dollars extra versus wafer-level, yet delivers instant hermeticity and proven sockets in telecom racks. SMD costs less in sheer materials yet demands tighter board tolerance on reflow curves. Pick based on volume, lifespan, and optical spec.

Road ahead for VCSEL packaging

Market forecasts bet on wafer-level as the volume king, but niche needs keep TO cans alive, and medical imaging still craves non-magnetic packge. Expect more hybrid lids, such as glass-polymer laminates with molded micro-optics, giving design teams laptop-camera thinness without sacrificing power.

Wrap-up

Packaging isn’t merely a box around a laser—it’s the handshake between physics, reliability, and your product dream. From trusty TO-46 cans to wafer-scale caps, each choice bends cost, heat, and beam shape in unique ways. Ace Photonics Co., Ltd. stands ready with custom headers, windows, and full VCSEL to match whatever wild idea you sketch next.